Optimising Asset Health From Reactive to Proactive: How Remote Condition Monitoring is Reshaping Maintenance Strategies and Machine Reliability.

Remote Condition Monitoring – Monitor Assets Affordably with Cloud-Based IIoT Sensor Technologies

What is Remote Condition Monitoring (RCM)?

Remote condition monitoring (RCM) is the practice of tracking equipment performance by collecting critical data from assets in remote locations, typically through wireless sensors, to monitor an asset's performance.

This is performed for equipment health diagnosis to detect potential faults and issues before they occur, enabling a strategic approach to maintenance and reducing unscheduled downtime. With the increased importance of machine uptime and reliability in industrial and manufacturing settings, remote condition monitoring has become an essential tool for facility and asset managers.

One of the biggest challenges in maintenance is dealing with intermittent equipment issues. These issues can be difficult to diagnose and may occur sporadically, making it challenging to predict when they will happen. Remote health monitoring solutions can address this challenge by providing real-time data monitoring of machine data enabling 'dumb' machines to talk and have a voice regarding their health. This enables maintenance teams to detect potential problems early, support making more informed maintenance decisions and helping to prevent unexpected failures and unscheduled downtime.

The use of cloud-based technologies has helped to scale remote condition monitoring, making it more accessible and affordable for companies of all sizes. With the Industrial Internet of Things (IIoT), machine data can be collected in a cost effective manner and connected to cloud-based software for comprehensive information management and insights.

Real-Time Data Monitoring: The Key to Improved Asset Health Through Remote Monitoring

What are the Benefits of Remote Condition Monitoring?

Remote condition monitoring uses sensors (often also referred to as online condition monitoring) enables real-time data monitoring of critical assets. This allows for a proactive approach to maintenance and safety as potential issues can be detected early and maintenance teams can respond quickly to prevent equipment failure. By tracking machine performance and collecting data on an ongoing basis, maintenance teams can identify trends and patterns that can help to optimise equipment performance.

Optimisation of Maintenance Teams and Resources

Remote condition monitoring allows maintenance teams to optimise and control their resources by focusing their efforts on critical assets that require attention. By monitoring assets remotely, such as through vibration analysis, teams can respond more quickly to issues and plan maintenance activities in advance. This enables a more proactive approach to maintenance, reducing the need for reactive maintenance that can be costly and time-consuming, and instead promoting a predictive maintenance strategy that leverages Remote CM metrics.

Data-driven Decision Making for Improved Asset Performance from Condition Monitoring Sensors

The data collected through remote condition monitoring (including vibration or temperature and acoustic) and analysed through cloud based technologies can be used to make data-driven decisions that improve asset performance. Through the automated analysis of machine data, maintenance teams are supported in the timely identification of areas for improvement and can implement changes that can increase uptime and reduce costs.

For example, if the data shows a particular fault type that a particular asset is experiencing from abnormal readings or trends, maintenance teams can use this information to further investigate the cause of the issue and make changes to prevent future occurrences. When you consider most operating and manufacturing facilities have hundreds, and sometimes thousands, of machines, this automated analysis and real-time alerting removes the issues of finding a 'needle in a haystack".

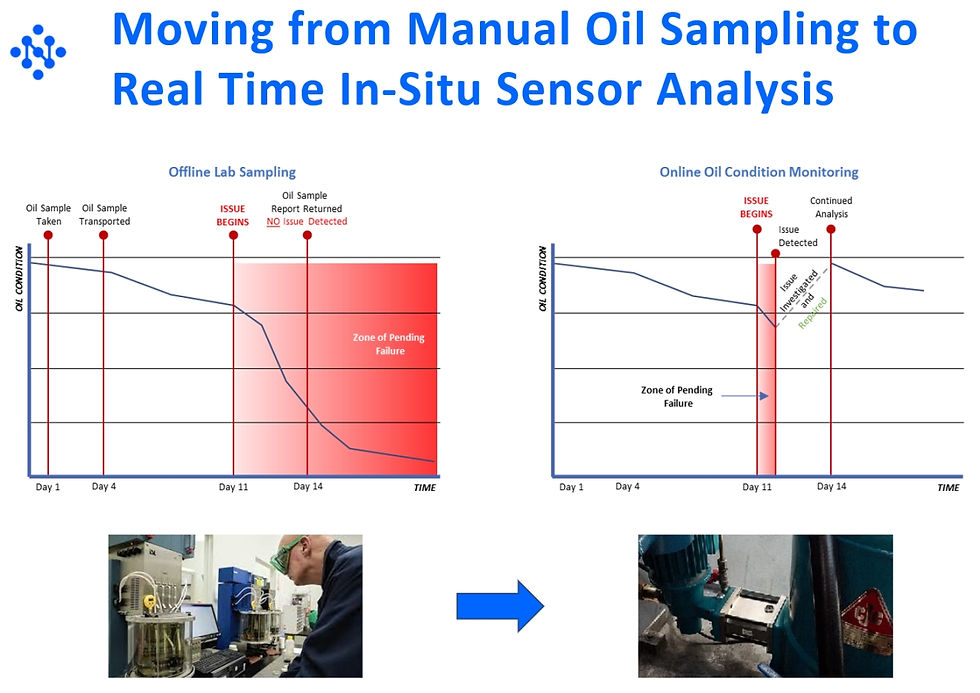

Read more about Online Oil Analysis with this article: Uncovering the Power of Fluid Analysis: Using Advanced Online Oil Condition Monitoring Sensors

Increased Uptime and Cost Reduction - the True Benefit of Online Condition Monitoring Systems

By automating complex assessments that can take much of an Engineer's time to resolve and detecting potential issues early, remote condition monitoring will support maintenance teams take corrective action well before a failure occurs, minimising downtime and reducing repair costs or making repairs more cost effective. In addition, by optimising maintenance activities and focusing resources on critical assets, companies can reduce the overall cost of maintenance.

Early Fault Detection and Predictive Maintenance with Vibration Sensors and Vibration Analysis

A remote condition monitoring program that is supported by a sound analytics platform allows for early warning fault detection notifications and predictive maintenance, which can help to prevent unexpected failures, reduce downtime or enable better planned schedule maintenance. By using wireless condition monitoring sensors (typically wireless vibration sensors and other sensor technology) to collect data more frequently of a machine's condition, maintenance teams can detect potential faults and respond quickly to prevent equipment failure, significantly improving maintenance and reliability. This enables a more proactive approach to maintenance, reducing the need for reactive maintenance, identifying issues before they escalate, minimising downtime and extending asset life.

Elevate your asset management and optimise your operations: take our online IIoT opportunity evaluation today for actionable insights.

The Role of Cloud-Based Technologies in Scaling Remote Condition Monitoring

Overview of Cloud-Based Technologies in Remote Condition Monitoring

Remote condition monitoring is an essential practice for any business that relies on critical assets for their operations. It involves collecting data from machines and equipment to track machine performance and identify potential faults before they occur, thus avoiding potential breakdowns. With the help of cloud-based technologies, remote monitoring has become more accessible and affordable than ever before, opening up the potential to implement predictive maintenance strategies to make greater step changes to existing maintenance programs.

Cloud-based software allows for real-time data collection, analysis and insights, which can be accessed from anywhere with an internet connection (referred to as 'data to the cloud'). This allows facility managers and maintenance teams to monitor assets in remote locations and respond quickly to any issues that arise. The data collected can also be used for condition-based maintenance, which helps to optimise maintenance frequency and reduce unscheduled downtime.

Mobile IIoT Devices in Remote Asset Management

Mobile Industrial Internet of Things (IIoT) devices, particularly those that provide LTE connectivity communication protocols for direct communication without the need for Gateways, play a vital role in remote asset management. The use of mobile devices, including vibration sensors, temperature sensors and acoustic sensors in cloud-based remote condition monitoring solutions allows for real-time data collection and informed decision-making and additionally support more consistent tracking of asset performance and maintenance needs.

By monitoring asset usage and performance, companies can optimise their maintenance schedules, reducing downtime and improving overall efficiency. Mobile IIoT devices also facilitate remote monitoring, enabling workers to access critical information from anywhere at any time. This is particularly useful for industries with remote or hazardous working conditions, such as mining or oil and gas facilities. Additionally, the ability to quickly and easily access asset data from mobile devices and be alerted directly means that workers can make more informed decisions and take immediate action when necessary.

For a comprehensive list of Frequently Asked Questions relating to Wireless Vibration Sensors, read this article: https://www.miniotec.com/post/comprehensive-faq-guide-wireless-vibration-sensors

Asset Criticality Assessments and Flexible Monitoring

An essential part of remote condition monitoring is conducting an asset criticality assessment to determine which assets are most critical to the business's operations. This allows for a strategic approach to monitoring and maintenance, ensuring that resources are allocated effectively. Flexible monitoring can be used to focus on specific assets during certain times of the year, such as batch and back-up equipment - e.g. fire water pumps.

Collaboration and Data Accessibility

Collaboration and data accessibility are critical components of a successful remote condition monitoring solution. With cloud-based technologies, data can be shared across multiple teams and departments, allowing for collaboration and better decision-making. By making data accessible to all stakeholders, companies can ensure that everyone is working towards the same goals.

Sensor and Work Order Automation

Sensor and work order automation can help to streamline the remote condition monitoring process. Automated work orders can be triggered by abnormal readings, ensuring that maintenance teams are notified promptly. Sensor automation can also help to reduce the guesswork and assumptions that come with manual data analysis, providing a more comprehensive and accurate view of asset performance.

Data Management and Security in Remote Condition Monitoring

Remote condition monitoring solutions have become increasingly popular in recent years as they offer numerous benefits to companies looking to optimise their maintenance processes and reduce costs. However, to fully realise the potential benefits of remote monitoring, it is crucial to have a comprehensive data management and security strategy in place. In this section, we will explore the key aspects of data management and security in remote condition monitoring.

Thorough Data Collection and Analysis for Actionable Insights

The success of remote condition monitoring largely depends on the quality and accuracy of the data collected. Remote monitoring solutions utilise wireless sensors to collect machine data, including vibration data and temperature readings, to track machine performance and identify potential faults. This critical data is then analysed using cloud-based software to provide actionable information to maintenance teams, allowing them to detect potential failures early on and make informed decisions about maintenance.

Workflow Management and Report Generation

To effectively manage remote monitoring systems, workflow management and report generation are essential. This process involves collecting, analysing and reporting on the data collected and thus enabling maintenance teams to make data-driven decisions about maintenance planning and asset management. By automating these processes, remote monitoring solutions enable companies to optimise maintenance workflows, reducing unplanned downtime and increasing asset uptime.

Data Transmission and Real-Time Tracking

Remote monitoring solutions rely on real-time data transmission and tracking to provide up-to-date information on machine performance. This data is transmitted wirelessly from the sensors to the cloud-based software, allowing maintenance teams to access critical data from anywhere, at any time. By leveraging the Industrial Internet of Things (IIoT), companies can access real-time data and insights to make informed decisions about maintenance and improve overall equipment performance.

Cloud Security and Scalability

Cloud-based technologies are a critical component of remote condition monitoring, enabling companies to access data and insights from anywhere. However, it is essential to ensure that these systems are secure to prevent data breaches and ensure uninterrupted access to critical data.

With numerous Cyber issues publicised in the media, and many other clandestine Cyber breaches not reported, companies are rightfully quite wary of some of the pitfalls of adopting IIoT solutions considering privacy and security issues are amongst the most considerable challenges of deploying IIoT devices. By choosing the right tools and technologies, companies can implement comprehensive data security strategies and ensure the scalability of their remote monitoring systems is manageable.

Centralised Data for Better Planning and Faster Response Times

One of the key benefits of remote monitoring solutions is the ability to centralise critical data for better planning and faster response times. By collecting machine data in a centralised system, maintenance teams, particularly those in back-to-back (B2B) or fly-in-fly-out (FIFO) working arrangements, can ensure no maintenance issues are missed and still quickly identify potential issues and respond to them in a timely manner. This enables companies to mitigate the risks of rolling workforces and associated gaps in knowledge transfer to reduce downtime and increase asset uptime, optimising maintenance processes and improving overall business performance.

Overcoming Challenges in Implementing Cloud-Based Remote Condition Monitoring

Remote condition monitoring solutions using Wireless IIoT devices have transformed the way we manage critical assets, allowing us to deploy devices easily without wires, detect potential faults early and make informed decisions that prevent unplanned downtime. However, implementing this technology can present some challenges. In this section, we will explore how to overcome these obstacles and ensure a successful implementation of cloud-based remote condition monitoring.

Multi-Site Operations and On-Site Inspections

One of the biggest challenges faced by facility managers and asset managers when implementing remote condition monitoring is managing multi-site operations and conducting on-site inspections, which can be mitigated through effective remote support systems. With assets spread across different locations, it can be difficult to collect critical data in a timely manner. However, this challenge can be overcome by leveraging cloud-based software and wireless IIoT solutions that provides real-time data from remote locations. For example, some wireless vibration sensors can do away with the need for a Gateway, making deployment and condition monitoring quick and reliable. Similar to how your smartphone connects to a cellular network, these vibration sensors can connect directly to the nearby cellular or LTE network. So it only takes 5 to 10 minutes to deliver a condition monitoring solution for predictive maintenance!

Automated Alarms and Abnormal Readings

Another challenge in remote condition monitoring is managing the large amount of data generated by sensors. Automated alarms and abnormal readings need to be addressed promptly to avoid unscheduled downtime. The solution is to use a comprehensive data analysis tool that can determine the criticality of each asset and send alerts to maintenance teams when necessary. This approach enables quick response times, reducing the risk of failures and associated costs.

Vibration Data and Data Silos

Vibration data is an essential component of remote condition monitoring, but it can be difficult to collect and analyse. Data silos and lack of collaboration between departments can further complicate the process. However, cloud-based technologies offer a scalable and flexible solution that allows for the integration of vibration sensors into the Industrial Internet of Things (IIoT) ecosystem. This enables comprehensive asset monitoring, providing valuable insights into equipment performance, temperature, acoustic (sound) and other critical parameters.

Data Security and Collaboration

Data security is a major concern for companies implementing remote condition monitoring solutions. It is essential to ensure that sensitive data is protected and that access is limited to authorised personnel. Collaboration between departments is also important to ensure that everyone has access to actionable information. This can be achieved by using cloud-based software with robust security features and collaboration tools that allow for real-time communication and sharing of data.

Ensuring ROI Improvements

Ensuring ROI improvements is a mandate many C-Suite leaders place on any expenditure for implementing condition monitoring solutions. To achieve this, it is necessary to take a strategic approach to maintenance and use data to optimise processes, reduce costs and increase asset uptime. By leveraging remote condition monitoring, maintenance teams can detect intermittent faults before they become major problems, spot potential issues before they occur and scale up operations as needed. A pilot program can be used to test the solution and refine work orders and failure codes. Mobile devices can be used to access data and resources and a computerised maintenance management system (CMMS) can be used to manage data silos and ensure a comprehensive approach to maintenance.

Notwithstanding, there are many aspects within a Digital Transformation strategy to consider when estimating ROI and it should not solely be based on saving manhours.

In Summary

Remote condition monitoring has become an essential tool for industrial and manufacturing settings. By utilising cloud-based technologies, it has become more accessible and affordable for companies of all sizes. The benefits of remote condition monitoring include improved asset health through real-time data monitoring, optimisation of maintenance teams and resources, data-driven decision making for improved asset performance, increased uptime and cost reduction. Furthermore, remote condition monitoring allows for early fault detection and predictive maintenance, reducing the need for reactive maintenance and minimising downtime, thereby boosting overall productivity.

Cloud-based technologies play a crucial role in scaling remote monitoring by allowing for real-time data collection, analysis and insights that can be accessed from anywhere with an internet connection. Mobile devices and wireless vibration sensors are also crucial components of remote condition monitoring, allowing for quick decision-making and response times.

Asset criticality assessment, flexible monitoring, collaboration, data accessibility and sensor and work order automation are also important factors in a successful remote condition monitoring solution.

However, it is crucial to have a comprehensive data management and security strategy in place to fully realise the potential benefits of remote monitoring. Thorough data collection and analysis, actionable insights are necessary for successful remote condition monitoring. Moreover, data security and privacy must be a top priority to protect sensitive information from cyber attacks and breaches.

In summary, remote condition monitoring brings many advantages for companies to improve asset health, reduce downtime and optimise maintenance processes. With cloud-based technologies, remote monitoring has become more accessible and affordable for companies of all sizes. By implementing a comprehensive data management and security strategy, companies can fully realise the potential benefits of remote condition monitoring and take a proactive approach to maintenance, reducing the need for reactive maintenance and minimising downtime.

Frequently Asked Questions

What is condition based monitoring?

Condition-based monitoring (or Remote condition monitoring) is the practice of tracking machine performance and collecting critical data from assets in remote locations through wireless sensors. This helps detect potential faults and issues before they occur, enabling a strategic approach to maintenance and reducing unscheduled downtime.

How does remote monitoring work?

Remote monitoring solutions typically use wireless sensors to collect machine data, such as vibration data and temperature readings. This critical data is then analysed using cloud-based software to provide real-time monitoring of critical assets. Potential issues can be detected, and in the best systems predicted, early and maintenance teams can respond quickly to prevent equipment failure.

Why is condition monitoring important?

Remote condition monitoring provides more consistent and informed data points to enable a more proactive approach to maintenance, improves asset health through continuous monitoring of equipment data, enables predictive maintenance strategies, optimises maintenance teams and resources, enables data-driven decision-making for improved asset performance and increases uptime and cost reduction.

Why is condition monitoring analytics? and What are the benefits of condition monitoring analytics?

Condition monitoring analytics refers to the systematic approach to tracking the performance of machinery to predict and prevent failures before they occur. It involves the use of data analytics tools and techniques to interpret information gathered from various monitoring equipment and sensors. By analysing parameters such as vibration, temperature and sound, businesses can gain insights into the machinery condition and take informed actions.

The benefits of condition monitoring analytics are multifaceted:

Predictive Maintenance: By leveraging condition monitoring analytics, businesses can transition from reactive to predictive maintenance strategies. This shift allows for the prediction of equipment failures and the scheduling of maintenance tasks before breakdowns occur, reducing downtime.

Enhanced Equipment Health State Analysis: Utilising vibration data, and the insights from vibration sensors, condition monitoring analytics helps determine the health state of equipment. This data, which can also be combined with information from infrared cameras and laser alignment systems, can be invaluable in assessing the internal condition of machinery without the need for disassembly.

Optimised Maintenance Schedules: Through analysis of the data collected, preventive maintenance schedules can be optimised, ensuring that maintenance is only performed when necessary. This approach saves time and resources, as maintenance is carried out based on actual equipment condition rather than on a set schedule.

Cost Reduction: With the aid of condition monitoring techniques, businesses can reduce costs associated with unplanned downtime and extend the lifespan of their machinery. By preventing major failures, companies can save on expensive repair costs and replacement parts.

Safety Improvements: Monitoring the condition of machinery also improves workplace safety. By identifying potential failures before they happen, the risk of accidents due to equipment failure is significantly reduced.

Remote Monitoring Capabilities: The advent of remote monitoring technologies, such as remote HVAC monitoring and wireless vibration sensors, allows for the continuous surveillance of equipment conditions from anywhere in the world. This capability is especially beneficial for industries with equipment located in remote or difficult-to-reach areas.

Efficient Resource Allocation: By understanding the equipment's health, resources can be allocated more efficiently. For example, remote equipment monitoring can indicate which machines require immediate attention and which can operate safely for longer periods, thus optimising the deployment of maintenance teams.

Condition monitoring analytics, with its blend of advanced technologies such as vibration sensors for machinery condition assessment and infrared techniques for thermal profiling, offers a comprehensive view into the operational readiness of critical industrial assets. As a result, businesses can not only prevent failures but also improve the overall efficiency and reliability of their operations.

How does remote condition monitoring improve maintenance safety?

Remote condition monitoring improves maintenance safety by utilizing sensors and software to monitor the health and performance of machinery and equipment. By providing real-time information on factors such as vibration and temperature, it allows for the early detection of any abnormality or irregularity in the system. This, in turn, enables maintenance personnel to identify and address issues before they cause significant problems.

Since the monitoring can be done remotely, it also helps in situations where the machinery is located in places that are difficult to access. This ability to remotely monitor ensures that maintenance resources are used efficiently, and potential hazards can be addressed without exposing workers to dangerous conditions. The constant stream of data serves as an indicator of the system's overall condition, and any deviations from the norm can become problems if not addressed promptly. Overall, remote condition monitoring enhances safety by allowing for timely maintenance and reducing the risks associated with manual inspections.

How does cloud-based technology help in remote condition monitoring?

Real-time data gathering, analysis, and insights are made possible by cloud-based technology, which can be accessible from any location with internet access. This makes it possible for facility managers and maintenance crews to receive updates to keep an eye on assets in distant areas and act promptly when problems do develop.

What is an asset criticality assessment?

Asset criticality assessments are an essential part of remote condition monitoring that determines which assets are most critical to the business's operations. This allows for a strategic approach to monitoring and maintenance, ensuring that resources are allocated effectively.

How does collaboration and data accessibility help in remote condition monitoring?

Collaboration and data accessibility are critical components of a successful remote condition monitoring solution, facilitating remote support and service tasks. With cloud-based technologies, data can be shared across multiple teams and departments, allowing for collaboration and better decision-making.

How can sensor and work order automation help in remote condition monitoring?

Sensor and work order automation can help to streamline and support the remote condition monitoring process. Automated work orders can be triggered by abnormal readings, ensuring that maintenance teams are notified promptly. Sensor automation can also help to reduce the guesswork and assumptions that come with manual data analysis, providing a more comprehensive and accurate view of asset performance.

How important is data management and security in remote condition monitoring?

Comprehensive data management and security strategy is crucial in remote condition monitoring to fully realise its potential benefits. Thorough data collection and analysis is necessary for actionable insights and ensuring the security of the data collected is vital for maintaining the integrity of the remote monitoring services.

What are the potential risks of remote condition monitoring?

The potential risks of remote condition monitoring include cybersecurity threats and privacy concerns. To mitigate these risks, it is essential to have a comprehensive data management and security strategy in place, including regular updates and maintenance of the remote monitoring system.

What types of assets can be monitored using remote condition monitoring?

Remote condition monitoring can be used to monitor various types of assets, including but not limited to industrial machinery across every sector, motors, HVAC systems, electrical equipment and transportation vehicles. Any asset that generates data can potentially be monitored remotely to detect potential faults and issues before they occur. Regarding IIoT devices, not every piece of equipment requires monitoring. The general consensus is that IIoT is most suited in monitoring equipment classified as having failure implications linked to "Serious" and "Marginal" categories, which generally accounts for around 70% of all machinery/equipment.

How does remote condition monitoring help with compliance and regulatory requirements?

Remote condition monitoring plays a crucial role in helping companies in the energy, industrial and manufacturing sectors comply with regulatory requirements. By continuously monitoring equipment and systems, companies can ensure compliance with regulations related to safety, emissions and efficiency.

For instance, in the energy sector, regulatory bodies such as the Environmental Protection Agency (EPA) have set emissions standards that companies must comply with. Remote condition monitoring helps companies ensure that their equipment and processes are operating within the prescribed limits, reducing the risk of non-compliance.

Similarly, in the industrial sector, regulatory bodies such as the Occupational Safety and Health Administration (OSHA) have set standards for workplace safety. Remote condition monitoring can help companies detect potential safety hazards before they lead to accidents, helping them comply with OSHA regulations.

How does remote condition monitoring impact maintenance budgets?

Remote condition monitoring can help reduce maintenance costs by enabling a more proactive approach to maintenance. By detecting potential issues early and optimising maintenance activities, companies can reduce the need for reactive maintenance that can be costly and time-consuming, saving tens of thousands of dollars, if not hundreds of thousands of dollars, if you also consider savings from reducing production losses. This can help to extend the lifespan of equipment and reduce repair costs. This can help to extend the lifespan of equipment and reduce repair costs.

What are the challenges associated with implementing a remote condition monitoring system?

Some challenges associated with implementing a remote condition monitoring system include data management and security, selecting the right sensors and software and integrating the system with existing infrastructure. It is important to have a comprehensive strategy in place to address these challenges before implementing a remote monitoring solution.

How can companies ensure that their remote condition monitoring service is effective?

To ensure that a remote condition monitoring system is effective, companies should conduct regular audits and assessments of the system. This includes the measurement and monitoring of data quality and accuracy, reviewing maintenance activities and analysing the impact of the system on uptime and maintenance costs. Companies should also engage with their maintenance teams to gather feedback and identify areas for improvement as their remote monitoring solution evolves.

Stay safe.

Let us know your thoughts?

Best;

About Miniotec:

Miniotec is a digital consulting and technology solutions provider, dedicated to supporting companies in their digital transformation journeys. Established by a group of experienced engineers, we emphasise the harmonious integration of people, processes and technology. Our team has a rich history of working across various sectors, from energy and resources to infrastructure and industry. We are trusted by the world's largest miners, oil and gas giants, utility companies and even budding start-ups and believe in the transformative power of the Industrial Internet of Things (IIoT) and its role in unlocking valuable data insights. Through IIoT, we aim to facilitate better decision-making, enhance operational activities and promote safer work environments. At Miniotec, our goal is to guide and support, ensuring every digital step is a step forward.

digital maintenance

online oil analysis

fluid condition monitoring

digital acceleration

digital transformation

wireless vibration

miniotec

.png)