Beyond the Initial Investment: We Explore How IoT Significantly Benefits Asset Lifecycle Management

Introduction:

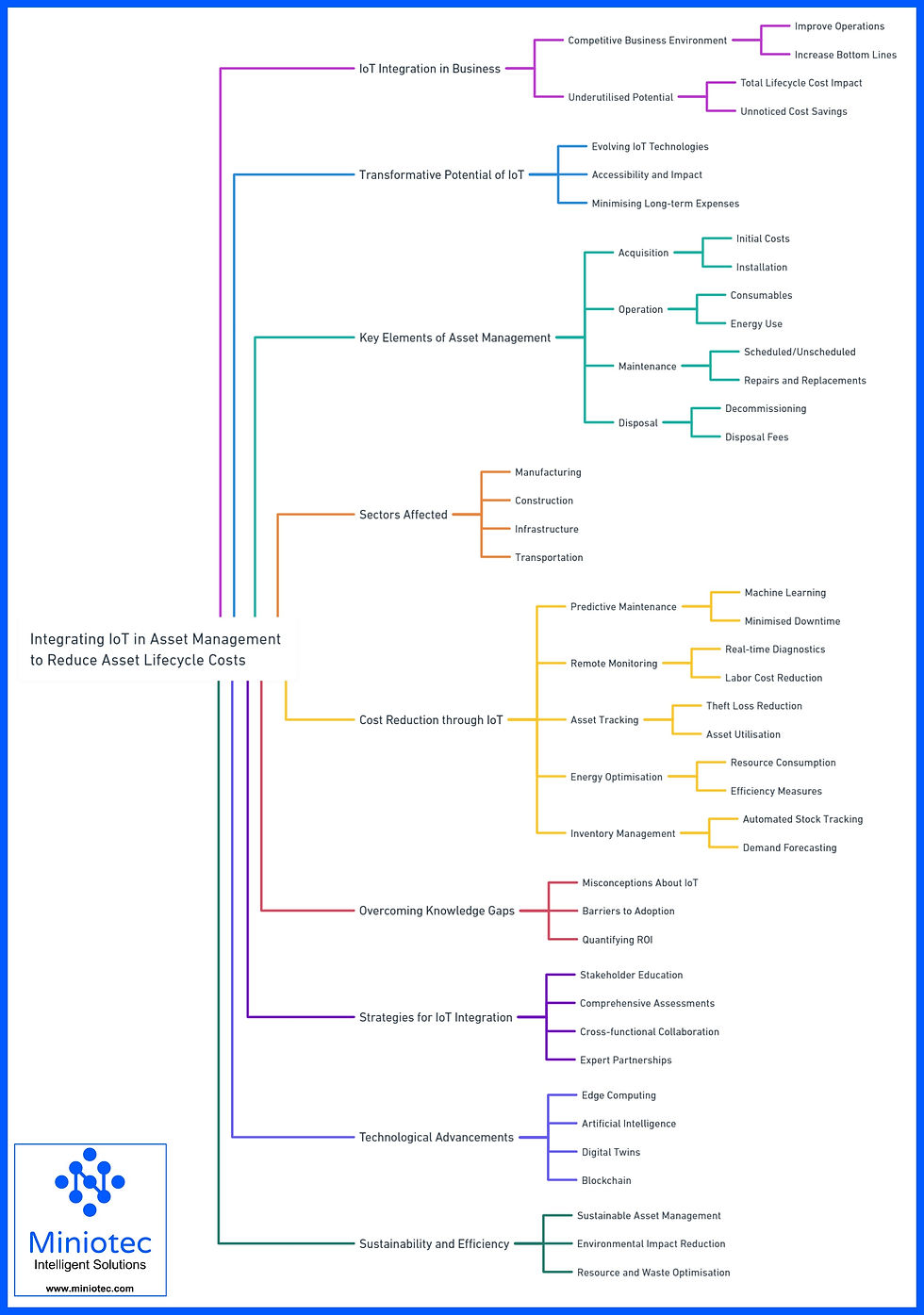

In today's fast-paced and competitive business environment, organisations are under constant pressure to improve their operations and increase their bottom lines. One area that is often under-scrutinised, yet can have a substantial impact on the bottom line, is the total lifecycle cost of assets. Whether it is manufacturing equipment, construction machinery, commercial buildings or critical infrastructure, the expenses associated with acquiring, operating, maintaining and eventually disposing of these assets can add up quickly, becoming a significant financial burden.

While the Internet of Things (IoT) has gained widespread recognition for its transformative potential across various industries, its role in reducing the total lifecycle costs of assets is frequently underappreciated or overlooked. As IoT technologies continue to evolve and become more accessible, they offer a powerful solution for organisations seeking to minimise the long-term expenses associated with their valuable assets.

The transformative capabilities of IoT in reducing total lifecycle costs within asset management systems are often underestimated, hindering organisations from maximising profitability and competitiveness.

Key Takeaways:

Total lifecycle costs of assets, spanning acquisition to disposal, can be a significant financial burden for organisations, making cost optimisation crucial for profitability and competitiveness.

The Internet of Things (IoT) offers powerful solutions for reducing total lifecycle costs through predictive maintenance, remote monitoring, asset tracking, energy optimisation, inventory management and data-driven decision-making.

Despite its potential, the role of IoT in reducing lifecycle costs is often overlooked or underappreciated, hindered by knowledge gaps, misconceptions and barriers to adoption.

Organisations must prioritise educating themselves and stakeholders on the transformative capabilities of IoT, conduct comprehensive assessments, foster cross-functional collaboration and seek guidance from experienced partners and experts.

Emerging technologies like edge computing, AI and digital twins unlock additional cost-saving potential in asset management, enabling more efficient operations and extending asset lifespans.

Incorporating sustainability into asset lifecycle management not only reduces environmental impact but also aligns with strategies for lowering total lifecycle costs through optimised resource use and waste reduction.

By embracing IoT as a strategic asset management tool, organisations can unlock significant cost savings, improve profitability and gain a competitive edge in their respective industries.

The Lifecycle Cost Burden

Total lifecycle costs encompass a multitude of expenses that span the entire lifespan of an asset, from initial acquisition to eventual disposal.

Organisations often struggle with the challenges of accurately forecasting and controlling lifecycle costs due to factors such as unpredictable maintenance needs, unplanned downtime, inefficient resource utilisation and the lack of comprehensive data and insights into asset performance and usage patterns.

What is the Total Lifecycle Costs of Assets?

Total Lifecycle Costs of assets refers to the comprehensive evaluation of all costs associated with an asset throughout its entire lifespan, from initial acquisition to final disposal. The key elements involved in calculating the total lifecycle costs include:

Initial Capital Cost: The upfront expenses for purchasing, installing and commissioning the asset. This includes the purchase price, delivery and any necessary setup or installation costs.

Annual Operating Costs: The ongoing expenses required to operate the asset, such as energy consumption, consumables, scheduled and unscheduled maintenance and labour costs. These recurrent costs can significantly impact the total lifecycle costs.

Periodic Replacements: The costs of replacing or refurbishing components of the asset at scheduled intervals over its useful life. This ensures the asset continues to function efficiently. as designed.

Additions and Alterations: Any modifications, upgrades or expansions made to the asset during its service life, which add to the overall lifecycle costs.

Use Costs: Expenses directly related to utilising the asset, such as training, monitoring or any additional costs incurred during regular operation.

Decommisioning and Salvage Value: These costs include decommissioning and disposal fees though there is also the potential value that can be recovered from the asset at the end of its useful life, either through resale or recycling. This can offset a portion of the total lifecycle costs.

Assets with high lifecycle costs can be found across various sectors, including manufacturing (e.g. production lines, CNC machines, robotic systems), construction (e.g. heavy machinery, cranes, excavators), mining (e.g. crushers, conveyors, reclaimers), oil and gas and petrochemicals (e.g. pumps, motors, turbines), transportation (e.g. vehicles, aircraft, ships) and infrastructure (e.g. buildings, bridges, pipelines). Failure to effectively manage and minimise these costs can lead to significant financial strain, reduced profitability and competitive disadvantages.

By considering all these elements, organisations can conduct a comprehensive Life Cycle Cost Analysis to make informed decisions about asset acquisition, operation and management, ultimately optimising the total cost of ownership.

Asset Type | Acquisition Costs | Operating Costs | Maintenance Costs | Disposal Costs |

Manufacturing Equipment | Purchase price, installation, commissioning | Energy consumption, consumables, labour | Scheduled maintenance, repairs, replacements | Decommissioning, waste disposal |

Construction Machinery | Purchase price, transportation, assembly | Fuel consumption, operator labour | Regular servicing, component replacements | Decommissioning, environmental remediation |

Commercial Buildings | Construction costs, land acquisition | Utilities, janitorial services, security | HVAC maintenance, repairs, renovations | Demolition, site cleanup |

Infrastructure (Bridges, Pipelines) | Construction costs, engineering, permits | Monitoring, inspection, security | Structural repairs, component replacements | Decommissioning, environmental restoration |

Table 1: Lifecycle Cost Components for Different Asset Types

IoT's Unsung Role in Cost Reduction and Transforming Asset Management

The Internet of Things has the potential to transform asset management, delivering considerable cost savings throughout the entire asset lifecycle. It is all about accessing a smart network of linked devices, sensors and cutting-edge analytics. With IoT, organisations get unprecedented visibility and control over their assets, opening up a whole new world of cost-saving potential. This is not simply an improvement; it is a full overhaul of asset management as we know it.

Predictive Maintenance - the Positive Outcome of IoT-Enabled Asset Management

One of the most powerful applications of IoT is its ability to enable predictive maintenance. By continuously monitoring asset performance and machine condition health through sensors that track variables like temperature, vibration and other operational data, IoT systems can leverage machine learning and predictive analytics to anticipate potential failures or maintenance needs before they occur. This proactive approach allows organisations to schedule maintenance activities at optimal times, minimising unplanned downtime and extending the lifespan of their assets.

Predictive maintenance enabled by IoT not only minimises unplanned downtime but also extends the lifespan of assets, optimising maintenance scheduling for enhanced operational efficiency.

Remote Monitoring and Diagnostics

IoT connectivity enables real-time remote monitoring and diagnostics of assets, even those located in remote or hard-to-reach locations, thereby enhancing asset management and reducing operational costs. This capability eliminates the need for frequent on-site inspections and maintenance visits, resulting in significant cost savings in terms of labour, travel expenses and logistical challenges.

Asset Tracking and Management

IoT devices equipped with location tracking capabilities can provide organisations with comprehensive visibility into the movement and utilisation of their assets. This real-time asset tracking can help optimise asset deployment, reduce losses due to theft or misplacement and ensure that assets are being utilised to their full potential, minimising the need for unnecessary purchases or redundancies.

Energy and Resource Optimisation

By integrating IoT sensors into buildings, factories and other facilities, organisations can monitor and optimise energy and resource consumption, such as electricity, water and raw materials. These insights enable the implementation of automated controls and efficiency measures, leading to reduced energy costs and extended asset lifespan through better resource management.

Inventory Management

IoT technologies can streamline inventory management processes by automating tracking and monitoring of stock levels, reducing the costs associated with overstocking, stockouts and manual inventory processes. Real-time visibility into inventory levels can also inform more accurate demand forecasting and procurement decisions, further optimising lifecycle operational costs.

Data-Driven Decision-Making

Perhaps the most significant advantage of IoT in asset management is the wealth of data it generates on asset performance, usage patterns and maintenance needs, enhancing asset management and monitoring. By leveraging advanced analytics and machine learning techniques, organisations can extract valuable insights from this data, enabling more informed and cost-effective decision-making throughout the entire asset lifecycle, from procurement to disposal.

IoT Application | Cost Savings Opportunities |

Predictive Maintenance | Reduced unplanned downtime, extended asset lifespan, optimised maintenance scheduling |

Remote Monitoring & Diagnostics | Reduced on-site visits, lower labour and travel costs and operational costs through the use of IoT-based asset monitoring and management |

Asset Tracking & Management | Improved asset utilisation, reduced losses, optimised deployment |

Energy & Resource Optimisation | Reduced energy and resource consumption, automated efficiency controls |

Inventory Management | Minimised overstocking and stockouts, streamlined processes |

Data-Driven Decision-Making | Informed procurement, maintenance and disposal decisions for cost optimisation |

Table 2: General Cost Savings from IoT Implementation

Optimising Total Lifecycle Costs Through IoT Integration: What are the Insights and Impacts?

While the initial capital cost and decommissioning phases of an asset's lifecycle may not directly benefit from IoT integrations, there is a significant scope for IoT technology to enhance cost efficiencies across other key elements.

As the asset enters its operational phase, the largest asset lifecycle cost segment at 40-60%, IoT's real-time monitoring capabilities become paramount. IoT solutions play a pivotal role by enabling real-time energy monitoring and predictive maintenance. This not only provides possibilities to reduce energy consumption but also curtails both scheduled and unscheduled maintenance expenses, thereby significantly lowering the recurrent operational costs.

In terms of periodic replacements, IoT's ability to forecast the optimal timing for component refurbishment or replacement ensures that assets operate efficiently without unexpected failures, streamlining the maintenance schedule and reducing associated costs. This predictive approach naturally extends to managing additions and alterations; IoT provides critical data on asset performance and utilisation, facilitating informed decisions on necessary upgrades or modifications.

Moreover, IoT significantly optimises use costs through advanced monitoring capabilities. By leveraging IoT sensors, organisations can streamline training and operational monitoring, minimising the resources and time typically required for mundane data collecting activities. Through continuous data collection and analysis, IoT offers a strategic advantage in maintaining operational efficiency and extending the useful life of assets, ultimately enhancing the overall asset management strategy without substantial increases to the lifecycle cost.

The Knowledge Gap: How Reducing Total Life Cycle Costs With IoT-Based Asset Management is the Opportunity

Despite the clear benefits of IoT in reducing total lifecycle costs, this potential often remains untapped or underutilised by organisations. A knowledge gap exists, where decision-makers may not fully comprehend the depth and breadth of IoT's impact on asset management and cost optimisation.

Common misconceptions or barriers to adoption include perceived complexities in implementing and integrating IoT solutions, concerns over cybersecurity and data privacy risks and a lack of in-house expertise or resources to effectively leverage the technology.

Additionally, some organisations may struggle to quantify the potential cost savings and return on investment (ROI) associated with IoT adoption, making it challenging to justify the initial investment and secure buy-in from stakeholders.

Bridging the knowledge gap on IoT's impact is crucial for organisations to unlock the full potential of cost savings and operational efficiency throughout the asset lifecycle.

Bridging the Gap: Why People Must Be Central to Any IoT-Based Asset Management and Monitoring

To bridge this knowledge gap and unlock the full potential of IoT in reducing total lifecycle costs, organisations must prioritise educating themselves and their stakeholders on the transformative capabilities of this technology. One effective approach is to conduct comprehensive assessments and cost-benefit analyses to quantify the potential cost savings and ROI that can be achieved through IoT implementation. This data-driven approach, facilitated by IoT data, can help build a strong business case and garner support from decision-makers and executives for asset management systems.

Additionally, organisations should foster cross-functional collaboration and adopt a holistic approach to IoT adoption. By involving stakeholders from various departments, such as operations, maintenance, IT and finance, organisations can ensure that IoT solutions are tailored to their specific needs and integrated seamlessly into existing processes and systems.

Partnering with experienced IoT solution providers and consultants can also be invaluable in bridging the knowledge gap. These experts can provide guidance on best practices, offer training and support and help organisations navigate the complexities of IoT implementation and data analytics.

Technological Advancements and Trends: Elevating Asset Lifecycle Cost Optimisation Even Further

As we delve deeper into the era of digital transformation, the rapid pace of technological advancements and emerging trends stand at the forefront of further refining asset lifecycle cost management. Innovations such as edge computing, artificial intelligence (AI), digital twins and the integration of blockchain into IoT ecosystems are reshaping the approach to asset management, promising even greater efficiencies and cost savings.

Edge Computing enhances IoT by processing data closer to its source, significantly reducing latency and bandwidth use. This immediacy allows for real-time data analysis and decision-making, improving the responsiveness of predictive maintenance and asset monitoring systems. By leveraging edge computing, organisations can achieve more agile and efficient operations, further reducing operational and maintenance costs, particularly where latency is a critical requirement.

The application of Artificial Intelligence and Machine Learning within IoT systems (AIoT) introduces sophisticated analytics capabilities, enabling more accurate predictions and smarter decision-making. AI algorithms can analyse vast datasets generated by IoT devices, uncovering patterns and insights that can lead to more effective asset utilisation and maintenance strategies, directly impacting lifecycle costs.

Digital Twins, virtual replicas of physical assets, enable organisations to simulate and analyse asset performance under various conditions. This powerful tool can optimise asset design, maintenance and operation processes, leading to significant cost reductions over an asset's lifecycle. By identifying potential issues and testing solutions in a virtual environment, companies can prevent costly real-world problems.

Blockchain Technology has the potential to offer enhanced security and transparency for IoT transactions and data exchanges in asset management systems. By creating tamper-proof records of asset history and maintenance, blockchain can improve trust in the data collected from IoT devices, supporting better decision-making and potentially reducing costs associated with fraud and data breaches. This technology's development and adoption is currently limited in IoT applications.

Embracing Sustainability Across the Asset Lifecycle: A Strategic Asset Management Imperative

Incorporating sustainability into asset lifecycle management is not just an ethical choice but a strategic business decision that aligns with cost reduction and operational efficiency goals. Sustainable practices, supported by IoT technologies, can significantly reduce energy consumption, lower emissions and minimise waste, contributing to a reduction in both environmental impact and lifecycle costs.

Energy and Resource Optimisation, a key benefit of IoT, plays a crucial role in sustainability efforts. By monitoring and managing the energy use of assets in real-time (an Energy Centred Maintenance strategy), organisations can significantly decrease their carbon footprint and utility costs. IoT-enabled smart buildings and factories represent prime examples of this optimisation, where automated systems ensure energy is used only when and where needed, leading to substantial savings.

Predictive Maintenance extends beyond cost savings, contributing to sustainability by preventing unnecessary consumption of spare parts and reducing waste. By accurately forecasting maintenance needs, organisations can ensure resources are used efficiently and responsibly, aligning with broader sustainability objectives.

Furthermore, Inventory Management Optimisations through IoT technologies can lead to reduced overproduction and excess stock, minimising waste and supporting leaner, more sustainable operations.

By integrating these technological advancements and emphasising sustainability, organisations can not only enhance their operational efficiency and reduce total lifecycle costs but also contribute positively to the environment. This strategic approach not only addresses the immediate financial bottom line but also positions businesses as leaders in the global move towards sustainable development. Through careful consideration of these elements, companies can navigate the complexities of modern asset management, achieving both economic and environmental success.

In Summary: The Union of Industrial IoT in Asset Management Strategies = Success in Operational Improvement

In an era where cost optimisation and operational efficiency are paramount, the role of IoT in reducing the total lifecycle costs of assets cannot be overstated. By leveraging the power of connected devices, sensors and advanced analytics, organisations can unlock a wealth of cost-saving opportunities through predictive maintenance, remote monitoring, asset tracking, energy optimisation, inventory management and data-driven decision-making.

However, the true potential of IoT in asset management often goes unnoticed or underappreciated, hindered by knowledge gaps, misconceptions and barriers to adoption. It is crucial for organisations to prioritise educating themselves and their stakeholders on the transformative capabilities of IoT, conduct comprehensive assessments, foster cross-functional collaboration and seek guidance from experienced partners and experts.

By bridging this knowledge gap and embracing IoT as a strategic asset management tool, organisations can achieve significant reductions in total lifecycle costs, improve profitability and gain a competitive edge in their respective industries. The time to unlock the hidden cost-saving potential of IoT is now.

Frequently Asked Questions

Q1. What are the operational cost benefits of integrating IoT into asset management?

Integrating IoT into asset management streamlines processes and provides real-time data, leading to significant operational cost savings. By automating asset tracking and monitoring, businesses reduce manual errors and enhance asset lifecycle management.

Q2. How does IoT technology supporting intelligent asset management strategies contribute to reducing downtime?

Technologies such as IoT enables predictive maintenance and remote asset governance, alerting managers to potential issues before they cause downtime. This proactive approach ensures equipment efficiency and overall asset health, minimising costly interruptions and thus increases asset uptime through improved asset information.

Q3. Can technologies like IoT-based asset management and monitoring improve operational efficiency?

Most definitely. By implementing asset management with IoT solutions, companies can gain insights from IoT sensors and management systems, which optimise asset workflow automation and streamline your asset management processes. This results in improved operational efficiency, smarter data-driven decisions and reduced costs associated with asset replacement.

Q4. In what ways does IoT asset tracking and monitoring transform asset management processes?

IoT asset tracking and monitoring offer transformative power by providing continuous visibility of asset conditions, thus allowing for informed decisions about asset maintenance and extending the asset's useful life, transforming asset management processes.

Q5. What role does IoT-based asset tracking play in asset lifecycle management?

The integration of IoT based asset tracking is instrumental in lifecycle management by providing comprehensive real-time asset data that aids in managing the asset portfolio efficiently and reducing the risk associated with asset replacement.

Q6. How can businesses harness the transformative power of IoT to enhance asset management and monitoring solutions?

Businesses can harness the power of IoT by, as an example, using IoT-enabled asset management software that integrates with existing systems for predictive analytics, thus saving costs and streamlining asset management processes.

Q7. What improvements can manufacturers expect from implementing IoT in asset management?

Manufacturers can expect significant improvements in asset efficiency, quality and the ability to make more informed decisions. Implementing IoT in manufacturing results in a robust asset management and monitoring solution that optimises the asset tracking and monitoring market.

We welcome your insights and experiences.

Stay safe.

Best;

About Miniotec:

Miniotec is a digital consulting and technology solutions provider, dedicated to supporting companies in their digital transformation journeys. Established by a group of experienced engineers, we emphasise the harmonious integration of people, processes and technology. Our team has a rich history of working across various sectors, from energy and resources to infrastructure and industry. We are trusted by the world's largest miners, oil and gas giants, utility companies and even budding start-ups and believe in the transformative power of the Industrial Internet of Things (IIoT) and its role in unlocking valuable data insights. Through IIoT, we aim to facilitate better decision-making, enhance operational activities and promote safer work environments. At Miniotec, our goal is to guide and support, ensuring every digital step is a step forward.

IoT in Asset Management

Lifecycle Cost Reduction

Predictive Maintenance

Asset Tracking and Optimisation

Sustainable Asset Lifecycle

Digital Transformation

Industrial IoT

AI in Maintenance

Equipment Reliability Optimisation

Smart Maintenance

Miniotec

.png)