An Insightful Outline of IIoT's Contribution to Efficiency, Sustainability and the Evolution of the Oil and Gas and Petrochemical Industries

Within the article we will consider:

Exploration of the role and benefits of wireless vibration sensors in enhancing efficiency and sustainability in the Oil and Gas and Petrochemical Industries.

Examination of real-world applications and case studies demonstrating the transformative impact of these sensors in predictive maintenance and energy management.

Insightful discussion on the future trends in machinery vibration monitoring, emphasising the growing significance of wireless vibration sensors in the evolving landscape of the Oil and Gas and Petrochemical Industries.

Introduction

In the ever-evolving landscape of the Oil and Gas and Petrochemical industries, the quest for improving efficiency is not just a goal; it's a necessity. The industries are a cornerstone of the global economy, powering our homes, fuelling our vehicles and providing raw and processed materials for a myriad of products. However, the industries are also under increasing pressure to reduce their environmental impact and improve their GHG footprint reduction strategies.

In light of the Paris Accord, every segment of the Oil and Gas and Petrochemical industries has the potential and, indeed, the responsibility to contribute to GHG reductions. This is where the role of wireless vibration sensors comes into play. These small, yet powerful devices are part of a broader IIoT strategy that can significantly contribute to more efficient practices, thereby reducing both industry's carbon footprint.

Wireless vibration sensors are a type of Industrial IoT sensor that measures the vibrations produced by industrial machinery, such as pumps, motors and rotating equipment. These sensors provide real-time machinery vibration monitoring, allowing for predictive maintenance and early warning of potential equipment failures. This capability not only enhances equipment reliability but also contributes to energy efficiency and reduced carbon emissions within the energy transition.

Elevate your asset management and optimise your operations: take our online IIoT opportunity evaluation today for actionable insights.

The relevance of these sensors in the Oil and Gas and Petrochemical Industries cannot be overstated. They are a key component of a digital transformation that is driving the industry towards Industry 4.0, Industry 5.0 and beyond. By providing actionable information and facilitating data-driven decision-making, wireless vibration sensors are helping to revolutionise asset health management and maintenance strategies in the sector.

In the following sections, we will delve deeper into the role of IIoT in the Oil and Gas and Petrochemical industries, the importance of predictive maintenance and the specific features and benefits of wireless vibration sensors. We will also explore real-world applications and case studies and look ahead to the future of vibration monitoring in the oil and gas and Petrochemical industries.

The Role of IIoT in the Oil and Gas and Petrochemical Industries

The Industrial Internet of Things (IIoT) has emerged as a transformative force in the Oil and Gas and Petrochemical Industries. It is a network of interconnected devices, including wireless vibration sensors, that collect, share and analyse data to improve operational efficiency and productivity.

Wireless vibration sensors are a crucial part of IIoT solutions. They provide real-time equipment monitoring, capturing vibration data from industrial machinery and transmitting it wirelessly for data analysis. This capability enables condition-based maintenance, where maintenance activities are scheduled based on the actual condition of the equipment, rather than on a predetermined schedule.

The impact of IIoT in the Oil and Gas and Petrochemical Industries is profound. By leveraging advanced analytics and machine learning for predictive maintenance, IIoT is transforming the way the industry operates. It is enhancing asset performance management, reducing equipment downtime and improving operational reliability. Moreover, by enabling remote condition monitoring, IIoT is making it possible to monitor hard-to-reach assets and hazardous location installations, thereby enhancing safety and reducing risk.

The Importance of Predictive Maintenance

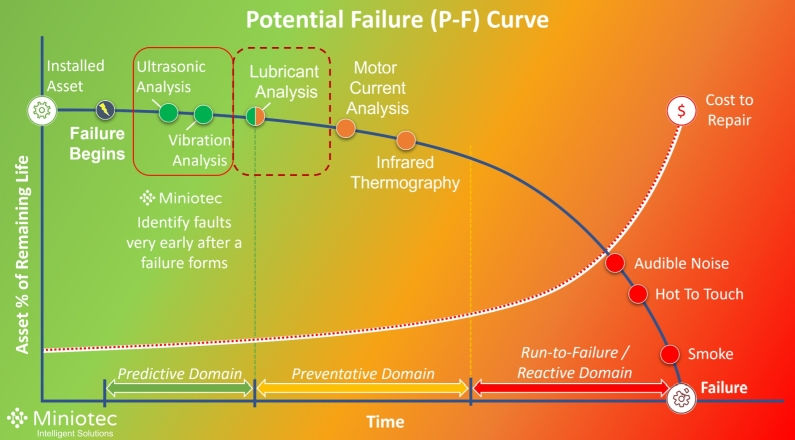

Predictive maintenance is a proactive maintenance strategy that uses data from machine monitoring sensors to predict equipment failures before they occur. This approach allows for timely maintenance actions, preventing costly equipment breakdowns and unplanned production outages.

Wireless vibration sensors play a pivotal role in effective predictive maintenance. They continuously monitor the vibrations of machinery, providing a wealth of machine health data. This data is then analysed to detect anomalies and predict potential failures.

For instance, an increase in vibration levels could indicate a problem with a bearing or a misalignment issue. By detecting such issues early, it's possible to schedule maintenance before a catastrophic failure occurs. This not only extends the lifespan of the equipment but also improves its efficiency and reliability.

Moreover, wireless vibration sensors offer several advantages over their wired counterparts. They are easy to install, can be placed in hard-to-reach areas and do not require complex cabling or infrastructure. They also offer long-distance communication, making them ideal for large industrial facilities.

Predictive maintenance, powered by wireless vibration sensors, is a game-changer for the Oil and Gas and Petrochemical Industries. It not only enhances operational efficiency but also contributes to significant cost savings by reducing the need for reactive maintenance and minimising equipment downtime.

Read about a successful case study with client recognised ROI here.

Understanding Wireless Vibration Sensors

As considered above, Wireless vibration sensors are at the heart of predictive maintenance strategies in the Oil and Gas and Petrochemical Industries. But how do these devices work and what sets them apart from other monitoring solutions? Let's delve into the details.

How Wireless Vibration Sensors Work

Wireless vibration sensors are devices that use wireless communication to transmit vibration data from a machine or other rotating equipment to a central monitoring system. This data can then be used to monitor the health of the equipment and identify potential problems before they cause a failure. Wireless vibration sensors work by using a sensor to measure the vibration of the equipment. The sensor then converts the vibration data into an electrical signal that is transmitted wirelessly to a remote monitoring system for data analysis.

There are two (2) main types of wireless vibration sensors: MEMS sensors and piezoelectric sensors. MEMS sensors are small, lightweight and low-cost, making them ideal for use in a variety of applications. Piezoelectric sensors are more sensitive than MEMS sensors, but they are also more expensive, larger and require regular re-calibration.

Key Concepts in Wireless Vibration Analysis

Vibration analysis is a critical aspect of condition monitoring. It involves examining the frequency and amplitude of vibrations to identify patterns that may indicate potential equipment failures.

Three (3) important parameters used to measure vibration are displacement, velocity and acceleration. Displacement refers to the distance a point on the machine moves from its rest position. Velocity is the speed of this movement and acceleration is the rate of change of velocity. These parameters provide valuable insights into the health and performance of machinery.

Features and Benefits of Wireless Vibration Sensors in Enhancing Efficiency in Oil and Gas

Wireless vibration sensors offer several features and benefits that make them ideal for the Oil and Gas and Petrochemical Industries. They are easy to install, require minimal maintenance and can operate in harsh and hazardous environments. Their wireless nature allows for remote condition monitoring, eliminating the need for manual inspections and reducing the risk of human errors.

Moreover, these sensors are capable of continuous monitoring, providing a constant stream of asset health data. This enables real-time condition monitoring and early warning of potential equipment failures, enhancing operational reliability and reducing maintenance costs.

Intrinsic Safety and Tier 1 Sensors

In the Oil and Gas and Petrochemical Industries, safety is especially paramount. Wireless vibration sensors used in this sector must be intrinsically safe, meaning they are designed to operate safely in potentially explosive environments. They are often Class 1 Div 1 IECEx certified (similarly ATEX certified) and have a high IP68 rating, indicating they are dust-proof and waterproof. Any lesser level specifications should be avoided.

Tier 1 sensors are the top-of-the-line devices that support predictive maintenance strategies. They stand out from lesser sensors with their multi-sensor capabilities and due to their ability to transmit large amounts of spectral data. These sensors not only measure vibration but can also monitor temperature, acoustics, magnetic flux and other parameters, providing a comprehensive view of equipment health.

Combined with their AI and Machine Learning capabilities, vibration sensors allow your rotating machinery to talk and are a vital tool in the Oil and Gas and Petrochemical Industries. They offer a powerful solution for predictive maintenance, helping to enhance efficiency, reduce costs and improve safety.

For more information on the impact of deferring maintenance, have a read of this article: "The True Cost of Deferred Maintenance".

Real-World Applications of Wireless Vibration Sensors in Oil and Gas

Wireless vibration sensors have a wide range of applications across various industries, including manufacturing, renewable energy and Mining. However, their use in the Oil and Gas and Petrochemical Industries is particularly noteworthy due to the sector's unique challenges and requirements.

Applications of Wireless Vibration Sensors in the Oil and Gas and Petrochemical Industries

In the Oil and Gas and Petrochemical Industries, wireless vibration sensors play a crucial role in condition monitoring and predictive maintenance. They are used to monitor a variety of equipment, including pumps, motors, gearboxes and other rotating machinery and heavy machinery.

These sensors provide real-time equipment monitoring, capturing vibration data that can be analysed to detect anomalies and predict potential failures. This capability is invaluable in an industry where equipment failures can lead to significant downtime, safety risks and financial losses.

Moreover, wireless vibration sensors are particularly useful in hard-to-reach areas and hazardous locations common in the Oil and Gas and Petrochemical Industries. Their wireless nature allows for remote condition monitoring, eliminating the need for manual inspections and reducing the risk of human errors.

Real-World Examples of Wireless Vibration Sensors in Action

Here we consider two (2) real-world examples of how wireless vibration sensors have been used in the Oil and Gas and Petrochemical Industries.

Remote Monitoring of Batch Pumping Equipment:

A major oil and gas company used wireless vibration sensors to monitor the health of pumping equipment that worked intermittently when oil tankers delivered crude oil to their refinery. The sensors provided critical vibration data every time the pumps operated, enabling the company to detect anomalies and schedule maintenance activities before future equipment failures could occur. This not only improved the reliability of the pumping equipment, ensuring they could always be available, but also enhanced the safety of their operations, reducing the need for manual route-based inspection and analysis as ships could berth at odd times.

Read how IIoT supports Digital Twins in Transforming The Energy Sector: "IIoT and Digital Twin Technology: Transforming Energy and Industrial Operations"

Predictive Maintenance in a Refinery:

A large refinery implemented a predictive maintenance program using wireless vibration sensors. The sensors were installed on various pieces of equipment, including pumps, motors and blower fans. The vibration data collected by the sensors was analysed using advanced analytics and machine learning algorithms to predict equipment failures. This allowed the refinery to schedule maintenance activities based on the actual condition of the equipment, reducing downtime and significantly reducing maintenance costs with a return on investment (ROI) measured in days.

These examples illustrate the significant benefits that wireless vibration sensors can bring to the Oil and Gas and Petrochemical Industries. By providing real-time, actionable information, these sensors are helping the industry enhance efficiency, improve safety and reduce costs.

Case Study: Implementing Wireless Vibration Sensors in Oil and Gas

To illustrate the transformative impact of wireless vibration sensors in the Oil and Gas and Petrochemical Industries, let's examine a real-world case study involving a large petrochemical plant.

Implementing Wireless Vibration Sensors at a Petrochemical Plant

The plant in question had a vast array of rotating equipment, including pumps, motors and gearboxes. The maintenance team was struggling with unscheduled downtime and high maintenance costs due to equipment failures. They were using a traditional route-based monitoring approach, which was time-consuming and often failed to detect problems early enough to prevent failures.

Recognising the need for a more proactive approach, the plant decided to implement a predictive maintenance program using wireless vibration sensors. The sensors were installed on critical equipment throughout the plant, providing continuous vibration monitoring and real-time equipment monitoring.

Results and Benefits of Wireless Vibration Sensors in Petrochemical Operations

The implementation of the wireless vibration sensors led to significant improvements in the plant's maintenance program. The sensors were each installed in less than 10 minutes, with no gateways or other wiring needed and thus provided a constant stream of machine health data almost immediately, enabling the maintenance team to detect anomalies and schedule maintenance activities before equipment failures could occur. This resulted in a substantial reduction in downtime and maintenance costs and enabled the maintenance team to use their time on more proactive activities to improve their overall maintenance program.

The decision to adopt a wireless solution over a wired one was driven by several factors. First, the wireless sensors were easier to install and required no complex cabling or infrastructure, reducing the initial cost and installation time. Second, the wireless sensors could be placed in hard-to-reach areas, providing monitoring capabilities that were not possible with wired sensors.

The choice of a sensor offering LTE connectivity over LoRaWAN, Bluetooth, Zigbee, Sigfox or Wireless Mesh alternatives was also a strategic decision. LTE offered several advantages, including higher data rates, which were essential for transmitting large amounts of spectral data required for true predictive maintenance strategies.

Moreover, the plant had previously experienced issues with gateway dropouts and was concerned about potential cybersecurity issues with gateways. LTE connectivity provided a more reliable and secure solution. Finally, the congested nature of the petrochemical plant meant that sensors with LTE connectivity had all-round capabilities, making them the ideal choice for this application.

This case study demonstrates the significant benefits that wireless vibration sensors can bring to the Oil and Gas and Petrochemical Industries. By providing real-time, actionable information, these sensors are helping the industry enhance efficiency, improve safety and reduce costs.

The Support of Wireless Vibration Sensors in Energy Management and GHG Footprint Reduction

In the era of growing environmental consciousness and regulatory compliance, the Oil and Gas and Petrochemical Industries are under increasing pressure to reduce their greenhouse gas (GHG) emissions. This is where wireless vibration sensors come into play, offering a novel approach to energy management and GHG footprint reduction within the energy transition.

Wireless vibration sensors, through their ability to track motor performance, can help approximate carbon footprints. Motors are among the largest energy consumers in the Oil and Gas and Petrochemical Industries. By monitoring the vibrations of these motors, the sensors can provide insights into their efficiency and energy consumption.

For instance, an increase in vibration levels can indicate a decrease in motor efficiency, which in turn can lead to higher energy consumption and GHG emissions. By identifying these issues early, corrective actions can be taken to improve motor efficiency, thereby reducing energy consumption and GHG emissions.

Moreover, the data collected by the sensors can be used to develop more energy-efficient operation strategies, further contributing to GHG footprint reduction. This aligns with the goals of the Paris accord, emphasising the potential of every segment of the Oil and Gas and Petrochemical Industries to contribute to GHG reductions.

The Future of Vibration Sensor Monitoring in the Oil and Gas and Petrochemical Industries

As we look towards the future, it's clear that vibration monitoring will continue to play a crucial role in the Oil and Gas and Petrochemical Industries. However, the nature of this role is set to evolve, driven by advancements in technology and changing industry needs.

5G / 6G are the next-generation wireless communication technologies that provide high-speed, low-latency and reliable data transmission for vibration monitoring systems. 5G / 6G can enable real-time data analysis and feedback, as well as support massive Internet of Things (IoT) devices for distributed sensing and control. 5G / 6G can also enhance the connectivity and interoperability of different vibration monitoring systems and platforms.

Edge processing is the concept of performing data processing at the edge of the network, rather than in the cloud or central servers. Edge processing can reduce the bandwidth and latency of data transmission, as well as improve the privacy and security of data. Edge processing can also enable local decision making and adaptive control for vibration monitoring systems, based on the data collected from local and easily deployable sensors.

Energy harvesting is the process of converting ambient energy sources, such as solar, wind, thermal, or kinetic energy, into electrical energy for powering devices. Energy harvesting can provide a sustainable and autonomous power supply for vibration monitoring sensors, especially in remote and inaccessible locations. Energy harvesting can also reduce the maintenance and replacement costs of batteries and wires.

Cyber security is another critical issue that vibration monitoring needs to address in oil and gas applications. Vibration sensors, particularly gateways, can be exploited by malicious actors for sabotage, espionage, or ransomware attacks. To prevent this, vibration monitoring systems need to implement robust encryption and authentication mechanisms to protect the data from unauthorised access or modification. They also need to continuously comply with relevant standards and regulations for cyber security in oil and gas and as hacking threats continually evolves.

Artificial intelligence (AI) is also anticipated to develop in a number of ways that will make wireless vibration sensors even more effective. AI algorithms are becoming increasingly sophisticated and they are able to learn more from large amounts of data. AI is also expected to evolve is in its ability to make better predictions where this information can be used to schedule maintenance before a failure occurs, which can prevent costly downtime. Additionally, AI is expected to advance in its ability to take action. AI can also help wireless vibration sensors to communicate and cooperate with each other, forming a smart network that can adapt to changing conditions and optimise the overall system performance. This means that AI can evolve to be used to shut down equipment before it fails, or to adjust the operating parameters of equipment to prevent damage.

Vibration monitoring in petroleum applications can benefit from the integration of 5G / 6G, Edge processing, Energy harvesting, cyber security and AI technologies. These technologies can improve the performance, reliability and sustainability of vibration monitoring systems, as well as enhance the safety and efficiency of petroleum based operations.

In Summary

The Oil and Gas and Petrochemical Industries are a complex and challenging environment, where efficiency, safety, and environmental responsibility are paramount. In this context, wireless vibration sensors provide a game-changing technology, offering a multitude of benefits that align with the industry's needs and objectives.

Wireless vibration sensors are a key component of Industrial Internet of Things (IIoT) solutions, providing real-time equipment monitoring and enabling effective predictive maintenance strategies. By detecting anomalies and predicting equipment failures, these sensors can significantly reduce downtime and maintenance costs, enhancing the overall efficiency and productivity of Oil and Gas and Petrochemical operations.

Moreover, wireless vibration sensors can contribute to energy management and GHG footprint reduction. By tracking motor performance, these sensors can help approximate carbon footprints, supporting the industry's efforts to reduce GHG emissions in line with the Paris accord.

The future of vibration monitoring in the Oil and Gas and Petrochemical Industries looks promising, with wireless vibration sensors set to play an increasingly important role. As we move towards a more connected and data-driven industry, the adoption of such technology will be crucial for maintaining a competitive edge.

The role of wireless vibration sensors in the Oil and Gas and Petrochemical Industries is transformative. They are not just tools, but strategic assets that drive operational efficiency, cost reduction, safety enhancement, and environmental sustainability.

As we navigate the future of this industry, the integration of such advanced technology is not merely an option, but a necessity for those who wish to thrive in an increasingly competitive and environmentally conscious world. Therefore, embracing wireless vibration sensors is a strategic move that will undoubtedly yield significant dividends in the journey towards a more sustainable and efficient energy sector.

For further case study examples, please refer here.

Frequently Asked Questions

Q: How does the integration of wireless vibration sensors align with the digital transformation goals in the oil and gas industry?

A: The integration of wireless vibration sensors is a key part of the digital transformation in the oil and gas industry. These sensors generate valuable data that feeds into digital twin models and advanced analytics platforms, enabling more data-driven decision-making. Being IIoT solutions, they are central to the industry's digital transformation goals. By providing real-time, actionable information, wireless vibration sensors help oil and gas companies to optimise their operations, improve efficiency and reduce costs.

Q: How do wireless vibration sensors contribute to predictive maintenance in the Oil and Gas and Petrochemical sectors?

A: Wireless vibration sensors are integral to predictive maintenance strategies in the Oil and Gas and Petrochemical industries. They provide real-time vibration data from machinery and equipment, enabling early detection of anomalies and potential failures. This allows maintenance to be scheduled proactively, reducing unscheduled downtime and associated costs.

Q: What sets apart Tier 1 wireless vibration sensors that support predictive maintenance strategies?

A: Tier 1 wireless vibration sensors stand out due to their ability to transmit large amounts of spectral data and their multi-parameter monitoring capabilities. They often include more than just one sensor in their device, providing a comprehensive view of equipment health. This enables more accurate condition monitoring and effective predictive maintenance.

Q: Why would a wireless solution be adopted over a wired solution in the Oil and Gas and Petrochemical industries?

A: The adoption of wireless solutions over wired ones in the Oil and Gas and Petrochemical Industries is driven by several compelling factors. Firstly, the installation of wireless sensors is significantly simpler and more cost-effective, especially in expansive or complex facilities where running extensive cabling can be logistically challenging and expensive.

Secondly, wireless sensors are ideal for monitoring equipment in hard-to-reach or hazardous areas, where installing and maintaining wired sensors can pose safety risks.

Thirdly, wireless vibration sensors offer flexibility and scalability. They can be easily added, removed, or repositioned as the needs of the operation change, without the need for extensive rewiring.

In contrast, wired solutions can be more susceptible to physical damage, require more maintenance, and their installation can result in significant operational disruption. Therefore, the benefits of wireless solutions in terms of cost, safety and flexibility make them a positive choice in these industries.

Q: How can wireless vibration sensors help in reducing the GHG footprint in the Oil and Gas and Petrochemical Industries?

A: Wireless vibration sensors can track motor performance, providing insights into their efficiency and energy consumption. An increase in vibration levels can indicate a decrease in motor efficiency, leading to higher energy consumption and GHG emissions. By identifying these issues early, corrective actions can be taken to improve motor efficiency, thereby reducing energy consumption and GHG emissions.

Let us know your thoughts?

Stay safe.

Best;

About Miniotec:

Miniotec is a digital consulting and technology solutions provider, dedicated to supporting companies in their digital transformation journeys. Established by a group of experienced engineers, we emphasise the harmonious integration of people, processes and technology. Our team has a rich history of working across various sectors, from energy and resources to infrastructure and industry. We are trusted by the world's largest miners, oil and gas giants, utility companies and even budding start-ups and believe in the transformative power of the Industrial Internet of Things (IIoT) and its role in unlocking valuable data insights. Through IIoT, we aim to facilitate better decision-making, enhance operational activities and promote safer work environments. At Miniotec, our goal is to guide and support, ensuring every digital step is a step forward.

WirelessVibrationSensors

Oil And Gas Industry

Petrochemical Industry

Predictive Maintenance

IIoT

Energy Efficiency

GHG Reduction

Digital Transformation

IOT

miniotec

.png)